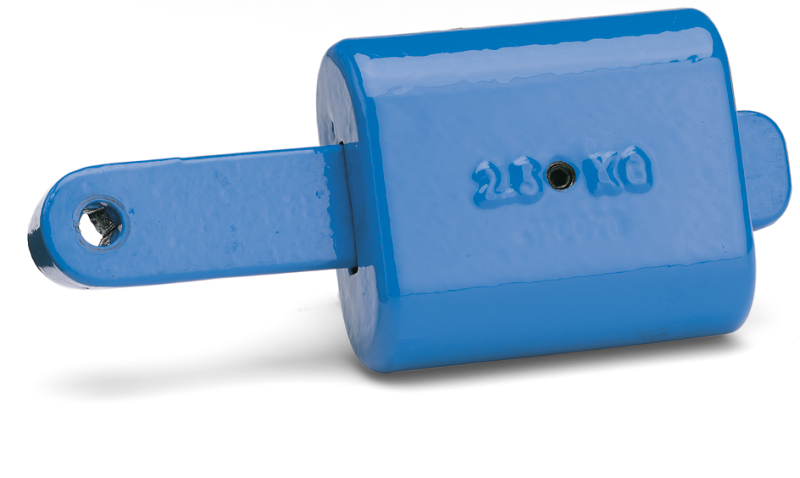

SWING CHECK VALVE, RESILIENT SEATED, PN10/16

Free shaft end RH side, brass-bushings, EN 558-48, SS shaft, EPDM, A2 bolts, 250µm blue EP coating

Resilient seat swing check valve, for drinking water and neutral liquids incl. treated waste water free of solids and fibrous impurities to max. 70°C

AVK series 41 swing check valves come with both metal and resilient seats to be installed in pumping applications to prevent back flow.

The disc is connected to the shaft via a flexible bush that allows disc and valve seat to adjust exactly and secure a tight seal.

All interior parts are stainless steel or coated with drinking water approved epoxy. Rubber parts are hydrocarbon resistant NBR or drinking water approved EPDM.

The series 41 valves are available with either enclosed shaft end or protruding shaft end where a lever with a weight or a spring can be fitted to mitigate pressure surges.

| Variant 41/60-003 | |

|---|---|

| Connection: | Flanged |

| Material: | Ductile iron |

| DN: | DN50 - DN300 |

| PN: | PN 16 |

Features

- Body and bonnet in ductile-iron

- Resilient seat provides a drop tight closure and the light weight of the disc requires a minimum of force to open

- Disc mounted loosely around a PA-bushing allowing it to tilt slightly in all directions and adjust exactly to the valve seat

- Shaft material stainless steel

- Stainless steel grade A2 bolts

- Disc core fully vulcanized with drinking water approved EPDM

- All seals in contact with the water in drinking water approved EPDM

- Bonnet gasket fixed in a groove between bonnet and body to prevent blow-out

- Free protruding shaft end for mounting of lever and weight or spring to assist valve closing and avoid water hammer

- 250µm fusion bonded blue RAL5017 epoxy coating, approved for drinking water

- Bosses on each side of the valve seat allow for installation of pressure gauge, by-pass, etc.

- Clear way and full bore for low head loss

- Shaft fitted in the bonnet allowing for easy maintenance without removing the valve from the pipeline

Downloads

Reference nos. and dimensions:

| Reference no. | DN mm |

Flange drilling |

H mm |

H3 mm |

L mm |

W mm |

D mm |

Theoretical weight/kg |

|---|---|---|---|---|---|---|---|---|

| 41-050-60-018 | 50 | PN10/16 | 120 | 202 | 200 | 232 | 165 | 12 |

| 41-065-60-018 | 65 | PN10/16 | 136 | 228 | 240 | 232 | 185 | 15 |

| 41-080-60-018 | 80 | PN10/16 | 135 | 235 | 260 | 237 | 200 | 16 |

| 41-100-60-018 | 100 | PN10/16 | 150 | 260 | 300 | 255 | 220 | 21 |

| 41-150-60-018 | 150 | PN10/16 | 212 | 354 | 400 | 332 | 285 | 47 |

| 41-200-60-008 | 200 | PN10 | 247 | 417 | 500 | 392 | 340 | 66 |

| 41-200-60-018 | 200 | PN16 | 247 | 417 | 500 | 392 | 340 | 66 |

| 41-250-60-008 | 250 | PN10 | 347 | 571 | 600 | 689 | 405 | 185 |

| 41-250-60-018 | 250 | PN16 | 347 | 571 | 600 | 689 | 405 | 185 |

| 41-300-60-008 | 300 | PN10 | 391 | 654 | 699 | 689 | 460 | 200 |

| 41-300-60-018 | 300 | PN16 | 391 | 654 | 699 | 689 | 460 | 200 |

Components

| 1. | Nut | Stainless steel A2 |

| 2. | Washer | Stainless steel A2 |

| 3. | Spacer | PA |

| 4. | Disc insert | Steel S275JR |

| 5. | Body | Ductile iron EN-GJS-500-7 |

| 6. | Bonnet gasket | EPDM rubber |

| 7. | Washer | Stainless steel A2 |

| 8. | Bonnet bolt | Stainless steel A2 |

| 9. | Disc rubber | EPDM rubber |

| 10. | Bolt | Stainless steel A2 |

| 11. | Washer | Stainless steel A4 |

| 12. | Hinge | Stainless steel AISI 316 |

| 13. | Bolt | Stainless steel A4 |

| 14. | Shaft | Stainless steel |

| 15. | O-ring | EPDM rubber |

| 16. | Bushing, open | Brass DZR CW602N |

| 17. | O-ring | EPDM rubber |

| 18. | O-ring | EPDM rubber |

| 19. | Bonnet | Ductile iron EN-GJS-500-7 |

| 20. | Key | Stainless steel A4 |

| 21. | Bushing, closed | Brass DZR CW602N |

Test/Approvals

- Hydraulic test according to EN12050-4

- Belgaqua approved material

- Approved according to 60143589, TÜV-Mark

- Approved according to WRAS Certificate No. 2312701 to max. 50°C

- Approved according to ACS-France

Standards

- EN 1074-3

- Face-to-face dimension according to EN 558, basic series 48

- Flange drilling to EN1092, PN10/16